Connecting Rod Processing Line

Some traditional connecting rod processing lines have many problems that perplex the development of enterprises. First, the conversion between the upper and lower process of the connecting rod processing line is difficult and the operators become loaders and porters. Second, the surface of the processed connecting rod is seriously bumped and scratched. The quality of the connecting rod is not guaranteed. Third, it is time-consuming and laborious, and the efficiency of labor is low. Fourth, it is difficult to realize the automatic loading and unloading of the connecting rod, because there is no way to automatically complete the conversion of the placement postures of the connecting rods.

Therefore, we recommend that the transformation and upgrading of some old connecting rod processing lines should adopt special conveyor belt for connecting rods as far as possible. The special conveyor belt for the connecting rod is used on the connecting rod processing line and between the upper and lower process. Automatic transmission of the connecting rod is realized between grinding machine. The whole transmission process does not need manual intervention. The labor intensity of workers is reduced.It also solves the appearance quality of the connecting rod. The efficiency is improved. The automation is also achieved.

Features and Advantages:

1. A lifting and lowering mechanism is installed on the connecting rod conveyor belt of the connecting rod processing line, which is used to adjust the height of the V-shaped trough and change the inclination angle of the conveyed connecting rod. It can meet the conveying requirements of connecting rods with different specifications. Height adjustment range: 60mm (can also be specially designed as required).

2. The width of the supporting rod of the connecting rod conveyor belt of the connecting rod processing line is adjustable. The width adjustment range is 30mm. (it can also be specially designed according to requirements so as to be suitable for connecting rods with different sizes).

3. The height of the supporting rod at the big end of the connecting rod of the conveyor belt on the connecting rod processing line is 800 mm above the ground. The height can be designed and adjusted according to requirements. The lower part is provided with an adjusting foot and a fixing bracket for fine adjustment.

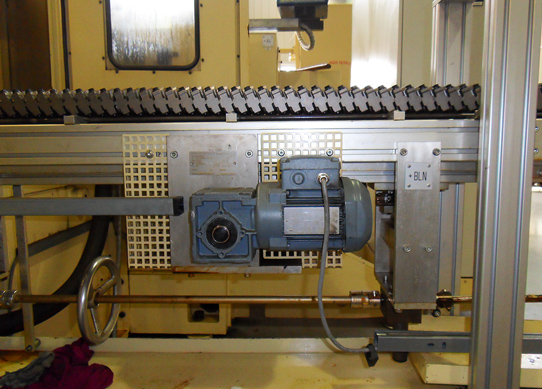

4. The connecting rod conveyor belt on the connecting rod processing line is driven by an integrated deceleration motor with a power of 0.25 KW.

5. The standard reciprocating stroke of the connecting rod conveyor belt on the connecting rod processing line is 12mm, which can also be designed according to requirements so as to meet various working rhythm requirements.

6. The connecting rod conveyor belt on the connecting rod processing line is provided with gantry supports.The maximum spacing between gantry supports is 1.6 meters.

7. The transmission mechanism of the connecting rod conveyor belt of the connecting rod processing line is provided with a safety guard net cover.

8. A liquid collecting tray is arranged at the lower part of the connecting rod conveyor belt on the connecting rod processing line to collect the lubricating oil or cleaning liquid dripping from the connecting rod. The liquid collecting tray is made of 1mm thick spray-painted plate.

9. The discharge port at the end of the connecting rod conveyor belt on the connecting rod processing line is equipped with a transverse blocking device to prevent the connecting rod from falling.