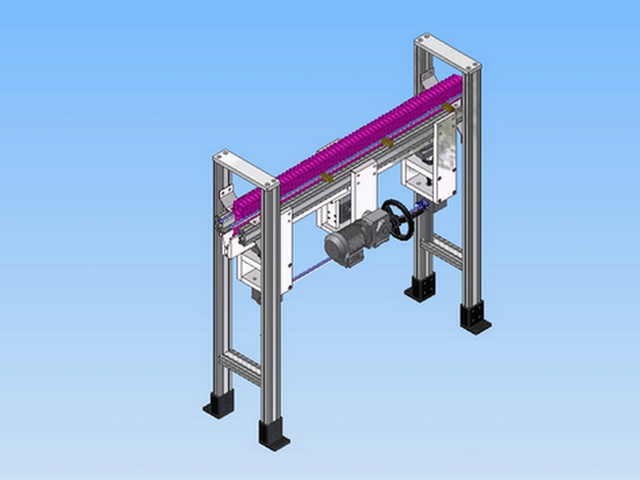

Connecting Rod Workpiece Belt

The connecting rod workpiece belt is mainly applied to the automatic transmission between the upper working process and the lower working process of the connecting rod production line.

The working principle of the connecting rod workpiece belt is as follows: The circular motion of the motor is converted into linear motion by using a deceleration motor with an eccentric wheel and a mechanical device, and drive the V-shaped trough of the conveyor belt to do reciprocating linear motion. The small end of the connecting rod is placed in the peristaltic trough of the connecting rod workpiece belt with the big end of the connecting rod supported by round supporting rods at two sides, which makes the connecting rod in an upright position with forward inclination. When the V-shaped trough moves forward, the friction force of the small end of the connecting rod is greater than the friction force of the supporting rod due to the action of gravity, the connecting rod moves forward. When the V-shaped trough moves backward, the friction force of the big end is greater than the friction force of the small end of the connecting rod, the connecting rod is kept still at this moment. When the V-shaped trough moves forward again, the connecting rod moves forward again by one step. The connecting rod moves forward in a peristaltic and stepping manner, so that the connecting rod is automatically conveyed according to the working target.

Features and Advantages:

1.A lifting and lowering mechanism is installed on the connecting rod workpiece belt to adjust the height of the V-shaped trough and change the inclination angle of the conveyed connecting rod, which can meet the conveying requirements of connecting rods with different specifications. Height adjustment range: 60mm (can also be specially designed as required).

2. The width of the support rod of the connecting rod workpiece belt is adjustable. The width adjustment range is 30 mm (It can also be specially designed according to requirements) so as to be suitable for connecting rods with different sizes.

3. The height of the supporting rod at the big end of the connecting rod of the connecting rod workpiece belt is 800 mm above the ground. The height can be designed and adjusted according to requirements. The lower part is provided with an adjusting foot and a fixing bracket for fine adjustment.

4. The connecting rod workpiece belt is driven by an integrated deceleration motor with a power of 0.25 KW.

5. The standard reciprocating stroke of the connecting rod workpiece belt is 12mm, which can also be designed according to requirements to meet various working rhythm requirements.

6. The connecting rod workpiece belt is provided with gantry supports. The maximum spacing between the gantry support is 1.6 meters.

7, The transmission mechanism of the connecting rod workpiece belt is provided with a safety protection net cover.

8. The lower part of the connecting rod workpiece belt is equipped with a liquid collecting tray to collect the lubricating oil or cleaning liquid dripping from the connecting rod. The liquid collecting tray is made of 1mm thick spray-painted plate.

9. A transverse blocking device is installed at the discharge port at the end of the connecting rod workpiece belt to prevent the connecting rod from falling.