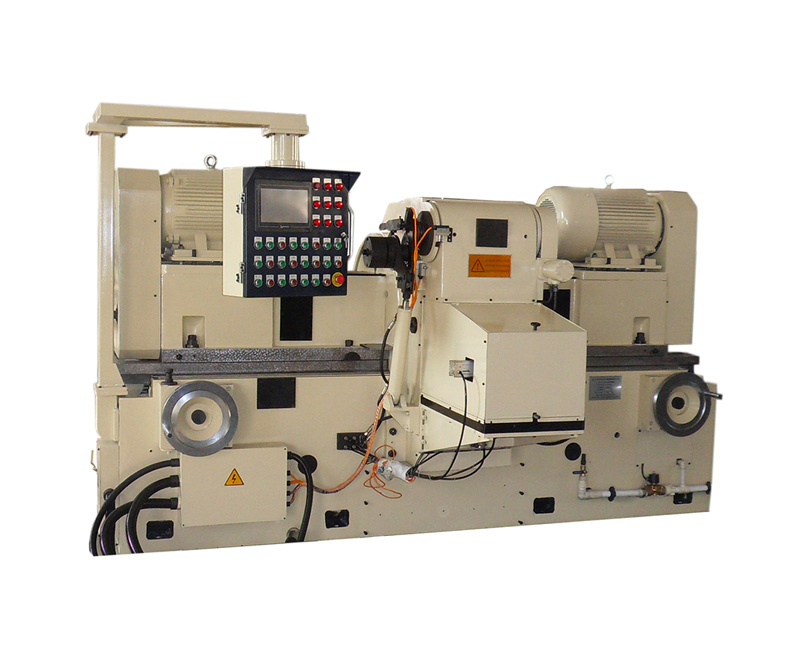

Connecting Rod Double End Grinding Machine LGM75C

1. Automatic feeding, automatic hanging arrangement of the material

2. The grinding connecting rod is isolated from each other to avoid collision with each other

3. Grinding wheel dressing frequency can be preset

4. Grinding wheel cover automatic lifting

5. The system has the function of historical data query

6. Grinding wheel wear to the limit size after the mechanical and electrical dual alarm and protection function

7. The grinding head moving using V-type steel needle roller guide

8. Dresser for the overall structure, two grinding wheels at the same time dressing

9. The water treatment system includes constant temperature refrigerator, magnetic separation system, paper tape filtration and purification system, three sets of pumps, two sets of water level control system, two sets of water tanks, two sets of slag car.

LGM75C connecting rod special double end grinding machine, is our company digest and absorb foreign advanced design concepts, self-developed through the high efficiency connecting rod special double end grinding machine, with independent intellectual property rights.

For small and medium-sized enterprises in Shandong Province, four plans to promote structural adjustment key projects, and won the provincial science and technology innovation award, participating in the identification experts agreed that the grinder design is novel and unique, fill the domestic blank, the overall technology is leading in the country, the use of high precision, stable performance, easy to switch varieties. It completely replaces imported equipment and is suitable for high-efficiency mass production of connecting rod automatic line.

Main features of machine tool:

1. Automatic feeding, automatic suspension arrangement, that is, to avoid bumps and bruises, but also reduce labor intensity, grinding and feeding time completely coincide.

2. The grinding connecting rod is isolated from each other to avoid collision with each other, and the feeding is stable, and there is no retention connecting rod in the grinding zone after shutdown.

3. Grinding wheel dressing frequency can be preset, after the number of processing reaches the set value, the grinding wheel automatically back dressing; After finishing, it automaticallyreturns to the grinding position, and the system automatically starts the feeding grinding without manual intervention.

4. The grinding wheel cover automatic lifting, and install the cover lifting and grinding head rotation interlock, dressing and grinding interlock safety device; The processing area is completely closed, and the discharge automatically washes; High degree of automation, large safety factor.

5. The system has the function of historical data query, can query the number of processing on duty and the cumulative number of processing, can also count the cumulative operation record of the machine tool.

6. The grinding wheel wear to the limit size after the mechanical and electrical dual alarm and protection function, when the grinding wheel consumption to the limit, the machine will automatically stop feeding, and alarm to do sound and light prompt.

7. The grinding head movement using V-type steel needle roller guide rail, the whole movement to achieve grinding, strong rigidity, the main shaft installed constant force load pre-tightening system, large cutting tool, high precision.

8. The dresser is the whole structure, two grinding wheels at the same time dressing, rigid foot, high dressing precision, and automatic dressing, automatic compensation.

9. The water treatment system includes constant temperature refrigerator, magnetic separation system, paper tape filtration and purification system, three sets of pumps, two sets of water level control system, two sets of water tanks, two sets of slag car.

Machine working accuracy:

Parallel error | 0.01(150) |

Flatness | 0.01(150) |

Thickness difference | 0.015mm |

Surface roughness | Ra0.8μm |

Main technical parameters (specific parameters are designed according to requirements):

Item | Unit | Argument |

Connecting rod length | mm | 80-400 |

Connecting rod thickness | mm | 15-60 |

Grinding wheel diameter (outer diameter × thickness × inner diameter) | mm | 750×60×50 |

Spindle speed | r/min | 770 |

Feed speed (stepless) | m/min | 3-14 |

Corrector movement speed | m/min | 0.5-1.5 |

Grinding head travel | mm | 130 |

Grinding machine | kw | 22×2 |

Overall dimensions (L × W × H) | mm | 3500×3400×1800 |

Weight | kg | 12000 |

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible