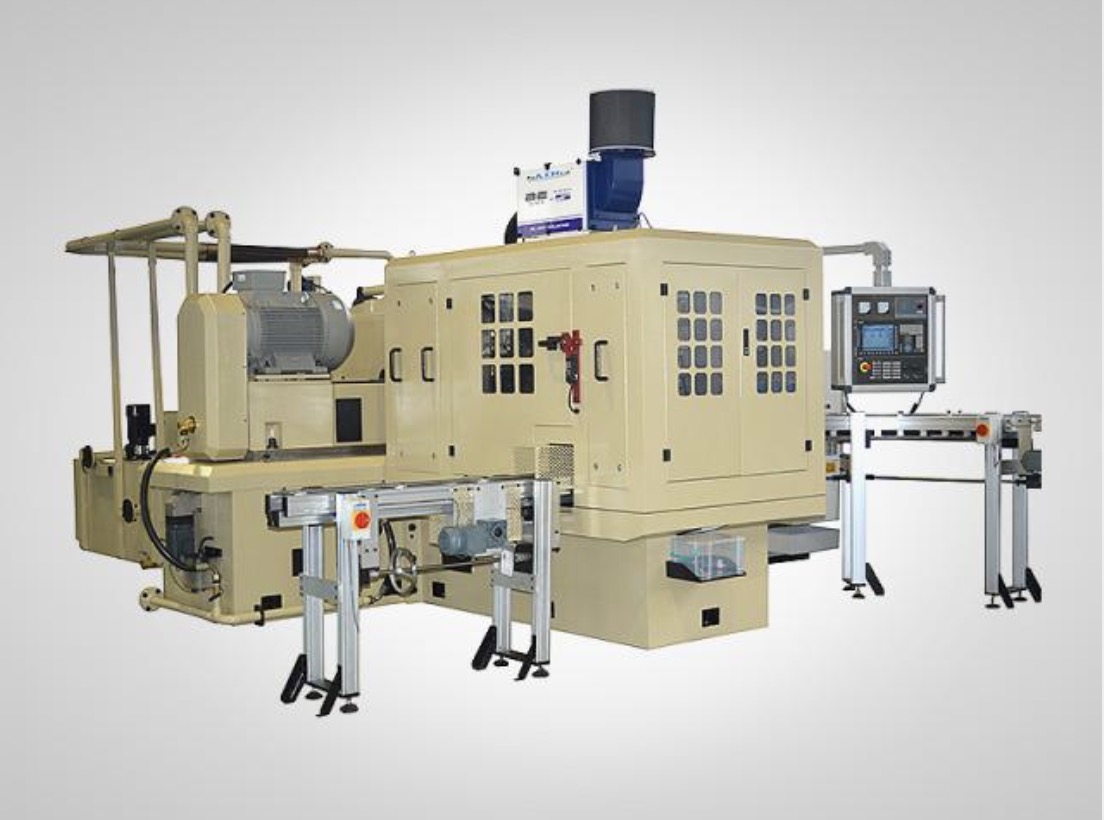

Double Face Grinding Machine

1. Increased Efficiency: Double face grinding machine have two grinding surfaces, allowing for simultaneous grinding of both sides of the workpiece. This results in faster grinding times and increased productivity.

2. Improved Accuracy: With two grinding surfaces, double face grinding machine offer improved accuracy and consistency in grinding operations. This is especially beneficial for achieving precise dimensions and tight tolerances.

3. Versatility: Double face grinding machine can be used for a wide range of applications, including flat grinding, parallelism, and thickness control. They are suitable for grinding various materials, such as metals, plastics, ceramics, and composites.

Prouct description

Double face grinding machines are commonly used in industries such as metal fabrication, automotive, aerospace, and tool manufacturing. They are ideal for grinding large workpieces or for applications that require precise parallelism, flatness, or thickness control. Overall, double face grinders are versatile and efficient machines that help achieve accurate and high-quality surface finishes on a variety of materials.

flatness | 0.01 mm |

Parallelism | 0.01 mm |

Difference of the thickness | 0.015 mm |

Roughness | Ra0.8µm |

Length of the connecting rod | 50 – 180 mm |

Thickness of the connecting rod | 10 – 40 mm |

Diameter of the grindstone | 500 x 60 x 30 mm (outer x thickness x internal) |

Rotation speed of the spindle | 1060 ( r/ minute ) |

Processing cycle | 3 seconds |

Speed of the trimming device | 0.5 – 1.5 m per minute |

The stroke of the grinding head | 120 mm |

Power of the grinding head motor | 7.5 x 2 KW |

Outer dimension of the machine | 2500 x 2400 x 1800 mm |

Weight of the machine | 5500 kgs |

Product advantages

1. Cost Savings: Double face grinders can help save costs by reducing the need for additional machining operations. The simultaneous grinding of both sides of the workpiece eliminates the need for flipping or repositioning, saving time and effort.

2. Reduced Operator Fatigue: Double face grinders are designed to be ergonomic and user-friendly. They typically feature adjustable work rests, easy-to-use controls, and safety features that help reduce operator fatigue and improve overall comfort during grinding operations.

3. High-Quality Surface Finish: Double face grinders are capable of achieving a smooth and uniform surface finish on the workpiece. This is important for applications where surface aesthetics and quality are critical, such as for parts used in automotive, aerospace, and medical industries.