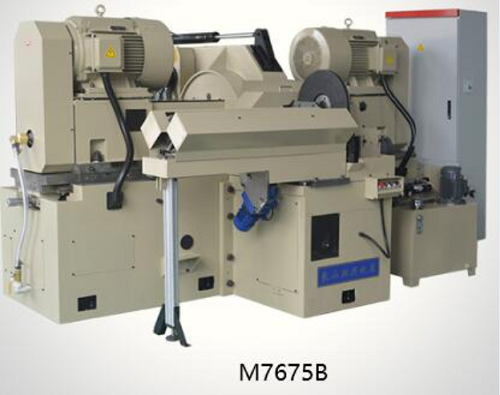

Horizontal Axis Go-Through-Type Double Face Grinder

Double-sided grinding machine is a type of machine that uses two rotating abrasive wheels to simultaneously grind both sides of a workpiece. This innovative machine offers several advantages over traditional single-sided grinding machines.

1. The machine tool has compact layout, scientific and reasonable design, strong rigidity, long service life, simple operation and convenient maintenance.

2. The grinding wheel cover can lift automatically, and all work units are equipped with safety interlocks, so the safety factor is reliable.

3. Frequency converter can be installed to complete stepless speed regulation of grinding head and realize differential grinding.

4. Servo motor and touch screen can be installed for numerical control.

Main features of machine tools:

M7675B series horizontal axis go-through type double-end grinder, which integrates the advantages of domestic and foreign horizontal axis double-end grinders, is designed and manufactured according to the specific situation in China, and the key components are all made of domestic Brands. It is an ideal machine tool for grinding multi-specification products by this single machine tool. Its outstanding features are strong rigidity, good stability, high precision, low energy consumption, complete functions, low failure rate and simple maintenance.

1. The grinding head moves integrally to finish grinding, with strong rigidity and outstanding stability.

2. The spindle has been subjected to six times of hot working, and the bearing adopts the combination of double-row short cylinders and angular contact ball bearings, and is equipped with a constant force load pre-tightening mechanism. The spindle has high precision, good rigidity and long service life.

3. The guide rail adopts V-shaped needle roller guide rail, and the feeding adopts high-precision ball screw.

4. The fast forward and backward movement of the grinding head and the pre-tightening force are maintained by hydraulic pressure, which is safe and reliable.

5. The dresser is an independent overall structure with sufficient rigidity and high dressing precision, and two grinding wheels can automatically dress at the same time.

Machine tool working accuracy

Parallel difference | 0.003mm |

| Flatness | 0.004mm |

| Thickness difference | 0.01mm |

| Surface roughness | Ra0.32μm |

Main technical parameters of the machine tool

Project | Single bit | Parameter number |

| Workpiece diameter | mm | 30—260 |

| Workpiece thickness | mm | 1.5-60 |

| Grinding wheel diameter (outer diameter× thickness× inner diameter) | mm | 750×60×50 |

| Speed of mainshaft | r/min | 770 |

| Feeding speed | m/min | 2-12 |

| Corrector moving speed | m/min | 0.5-1.5 |

| Grinding head moving stroke | mm | 130 |

| Grinding head motor | kw | 22×2 |

Dimensions (length× width× height) | mm | 3500×3000×1850 |

| Heavy quantity | kg | 12000 |