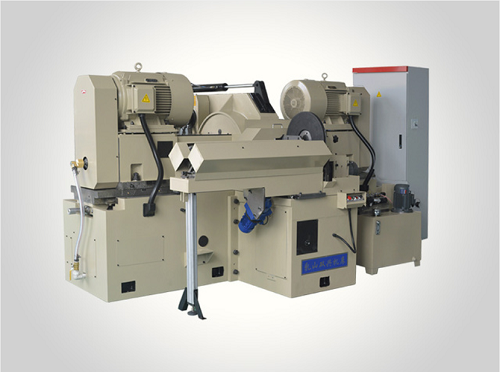

Horizontal Shaft Through Type Double Face Grinding Machine

Horizontal spindle double-disc grinding machines offer several advantages in grinding operations.

1. These advantages include.

2. Increased productivity.

3. Improved accuracy and consistency.

4. Versatility.

5. Easy automation integration.

6. Reduced setup time.

In conclusion, horizontal spindle double-disc grinding machines offer advantages such as increased productivity, improved accuracy and consistency, versatility in grinding different materials and surfaces, easy automation integration, and reduced setup time. These advantages make them highly efficient and reliable tools in various grinding operations.

Main features of machine tool:

1. The whole movement of the grinding head completes the grinding, with strong rigidity and outstanding stability.

2. The main shaft after six hot processing, bearing using double row of short cylinder and angular contact ball bearing combined, and installed constant force load preload mechanism, spindle high precision, good rigidity, long service life.

3. The guide rail adopts V-type inlaid needle roller guide rail, and the feed adopts high-precision ball screw.

4. The grinding head fast forward, fast back and the maintenance of pre-loading force, by hydraulic maintenance, safe and reliable.

5. The dresser is an independent overall structure, rigid foot, high dressing accuracy, two grinding wheels at the same time automatically dressing.

6. The machine layout is compact, the design is scientific and reasonable, the rigidity is strong, the service life is long, the operation is simple, the maintenance is convenient.

7. The grinding wheel cover automatic lifting, each working unit are with safety interlock, safety factor is reliable.

8. Inverter can be installed to complete stepless speed regulation of grinding head and realize differential grinding.

9. Can be installed servo motor, touch screen, CNC control.

Machine accuracy

Parallel error | 0.003mm(6309/1) |

Flatness | 0.004mm(6309/1) |

Thickness difference | 0.01mm |

Surface roughness | Ra0.32um |

The main technical parameters of machine tools

Item | Units | Parameter |

Workpiece diameter | mm | ¢30—¢260 |

Work piece thickness | mm | 1.5-60 |

Grinding wheel diameter (outer diameter× thickness × inner diameter) | mm | 750×60×50 |

Spindle speed | r/min | 770 |

Feeding speed | m/min | 2-12 |

Modifier movement speed | m/min | 0.5-1.5 |

Grinding head moving stroke | mm | 130 |

Grinding head motor | Kw | 22×2 |

Dimensions (L x W x H) | mm | 3500×3000×1850 |

Weight | kɡ | 12000 |