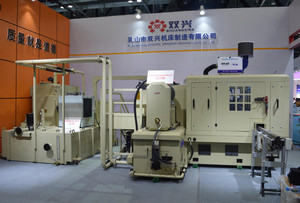

Parallel Grinder Machine

A parallel grinder machine, also known as a parallel grinding machine, is a type of grinding machine used to achieve parallelism, flatness, and precise dimensions on workpieces. It is commonly used in industries such as automotive, aerospace, tool manufacturing, and precision machining.

The parallel grinder machine typically consists of a grinding wheel or abrasive belt that is mounted on a rotating spindle or driven by a motor. The workpiece is placed on a flat surface or a magnetic chuck, and the grinding wheel or abrasive belt is moved across the workpiece to remove material and achieve the desired shape and surface finish.

Parallel grinder machines are designed to grind workpieces to very tight tolerances and maintain parallelism between surfaces. They are capable of grinding various materials, such as metal, ceramics, and plastics.

One of the key advantages of a parallel grinder machine is its ability to grind multiple workpieces simultaneously, improving productivity and efficiency. Additionally, the machine often features advanced control systems and automation, allowing for precise control of grinding parameters, such as speed, feed rate, and depth of cut, resulting in consistent and accurate grinding results.

Parallel grinder machines come in various configurations, including surface grinders, cylindrical grinders, and tool grinders, depending on the specific application and workpiece geometry.

Overall, a parallel grinder machine is a versatile and essential tool in precision grinding operations, ensuring the production of high-quality components with tight tolerances and parallel surfaces.

The general and main technical parameters of the grinding machine

Size of the grindstone (outer diameter x inner diameter x thickness) | 750×50×60 mm |

Connecting rod length to be ground | 100-268mm |

Connecting rod thickness to be ground | 18-30mm |

Motor power of the grinding head (2 pieces in total) | 22×2 KW |

Maximum moving stroke of the two grinding head | 130 mm (left head) 130mm (right head) |

Minimum feeding accuracy | 0.005mm |

Spindle rotation speed | 770 r/min |

Swinging speed of the grindstone trimmer(stepless) | 0.5-1.5 m/min(approximately) |

Processing cycle (stepless) | 3-8 seconds |

Gear pump | CB-25 |

Pressure of the oil line adjustment | 2-3.5MPa |

Motor power of the hydraulic pump | 2.2KW |

Total power of the grinding machine | 54KW (approximately) |

Gross weight of the grinding machine | 12 MT |

Dimension of the grinding machine layout (length × width × height) | 3500 × 3000 × 1800mm

|

For other detailed information, please contact us freely, hoping we can be your very reliable partner for you to have the world most advanced double face grinding machines for Connecting Rod industry and you reduce your production cost enormously, enlarging your profit possibility to a new level through our cooperation.