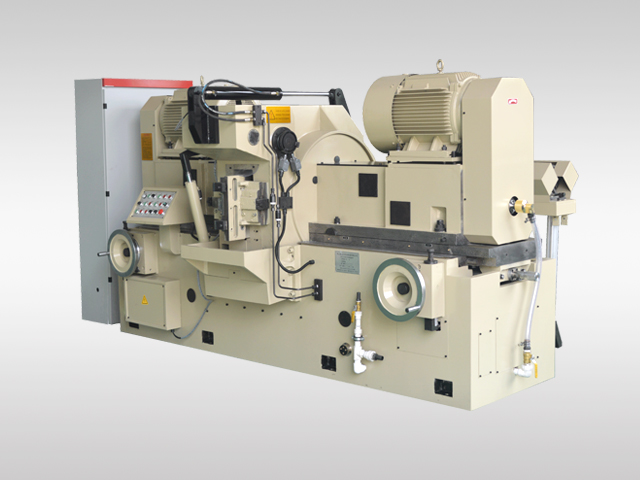

Bicycle Disc Brake Double Sided Face Grinding Machine

The working principle of this bicycle disc brake double sided face grinding machine is horizontal shaft through-type double sided face grinding machine. Our company combines the production process of bicycle disc brake and the specific requirements of bicycle disc brake to design and manufacture the machine. It belongs to the bicycle disc brake special double sided face grinding machine. Its outstanding characteristics are strong rigidity and high efficiency. The processing technology of bicycle disc brake pays attention to the beauty of the appearance of bicycle disc brake and the efficiency of production. In response to this demand of customers, our company has developed a set of special loading and unloading fixtures for bicycle disc brake manufacturers, which can automatically load and unload.

The bicycle disc brake ground by the special double sided face grinding machine has beautiful appearance. The production rate is high. And the bicycle disc brake double sided face grinding machine has high yield, and is highly praised by the bicycle disc brake industry.

Features and advantages :

1. The design of bicycle disc brake double sided face grinding machine solves the influence of grinding heat on the deformation of the machine tool, ensures that the machine tool works continuously for a long time, and has relatively good accuracy and stability.

2. The bicycle disc brake double sided face grinding machine is equipped with hydraulic system, which can successfully eliminate the ball screw clearance, prolong the life of the ball screw, and keeps the grinding machine in the best working condition all the time.

3. The double grinding heads of the bicycle disc brake double sided face grinding machine are continuously maintained by the pre-tightening force provided by the hydraulic pressure. The precision is stable. It can protect the machine tool through safety avoidance in case of special conditions such as grinding wheel breakage. The machine tool is safe and reliable.

4. The grinding head of the bicycle disc brake double sided face grinding machine adopts V-shaped steel inlaid needle bearing guide rail to realize grinding by integral movement instead of spindle telescopic movement, This maximizes its rigidity.

5. The key joint surface of the bicycle disc brake double sided face grinding machine is chipped and scraped manually. The bed layout is compact and the rigidity is strong. The spindle box has good sealing, long service life. It is simple to operate and convenient to maintain.

6. In order to prevent the phenomenon of grinding sparks between iron and iron from the bicycle disc brake double sided face grinding machine, when the grinding wheel is consumed to the limit size, the machine tool will automatically stop working and give an audible and visual alarm prompt.

7. For the bicycle disc brake of the double sided face grinding machine, there is safety interlocking between the lifting - lowering action of the grinding wheel protective cover and the rotation of the grinding wheel. There is safety interlocking between trimming and grinding. The automation degree is high. The safety factor is large.

Working accuracy of machine tool (different workpieces have different accuracy):

| Parallel difference | 0.01mm |

| Thickness difference | 0.03mm |

| Surface roughness | Ra 0.32um |

Main technical parameters of the machine tool:

| Project | Unit | Parameter |

| Workpiece diameter | mm | ¢30—¢260 |

| Workpiece thickness | mm | 1.5-60 |

| Grinding wheel diameter (outer diameter × thickness × inner diameter) | mm | 750×60×50 |

| Spindle speed | r/min | 770 |

| Feeding speed | m/min | 2-12 |

| Trimmer movement speed | m/min | 0.5-1.5 |

| Moving stroke of grinding head | mm | 130 |

| Grinding head motor | Kw | 22×2 |

| Overall dimension (L × W × H) | mm | 3500×3000×1850 |

| Weight | kɡ | 12000 |