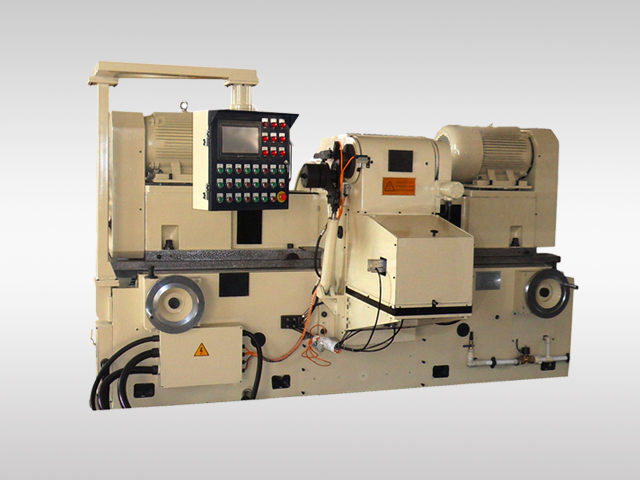

Double Sided Face Grinding Machine

Double sided face grinding machine is widely used in automobile, mobile phone, new materials, new energy, aviation, heavy industry, light industry and other industries such as bearings, connecting rods, gears, brake discs, ceramic pieces and other products. The double sided face grinding machine can be used in all workpieces as long as the two end faces of the workpices need to be ground. No matter it is metallic, non- metallic, round, square or rectangular workpiece, the double sided face grinding machine all has successful examples in grinding it.

The double sided face grinding machine we produce is easy to operate, has strong versatility. The automation degree is high. The machine possesses multiple independent intellectual property rights.

Features and advantages:

1. Thermal insulation design: The design of the double sided face grinding machine solves the influence of grinding heat on the deformation of the machine tool, ensures that the machine tool works continuously for a long time. The double sided face grinding machine has relatively good accuracy and stability.

2. Clearance elimination function: The double sided face grinding machine is equipped with hydraulic system to successfully eliminate the ball screw clearance, which not only prolongs the life of the ball screw, but also keeps the grinding machine in the best working condition.

3. Strong rigidity: The grinding head of the double sided face grinding machine adopts V-shaped steel-inlaid needle bearing guide rail to realize grinding by integral movement instead of spindle telescopic movement. It maximizes its rigidity.

4. Core components: The main shaft of the double sided face grinding machine is made of 40Cr material, which has been subjected to forging, annealing, normalizing, quenching and tempering, high-frequency quenching and stability treatment. The guide rail is made of Gr15 material. The inlet and outlet workpiece plate is made of 65Mn material.

5. Grinding wheel limit protection: In order to avoid the phenomenon of sparks of grinding between iron and iron, when the grinding wheel is consumed to the use limit, the machine tool will automatically stop, and sound and light alarm prompt will be provided.

6. Safety interlock configuration: There is safety interlocking between grinding wheel protective cover lifting- lowering action and rotation of the grinding wheel. There is safety interlocking between trimming and grinding.The automation degree is high. The safety factor is high.

7. High-altitude cable rack: The cable communication between the double sided face grinding machine and the power distribution cabinet adopts high-altitude wiring. The ground is barrier-free. The cable is not easy to be damaged, which does not hinder the walking of personnel. The safety factor is high.

8. High strength dressing arm: The dresser of the double sided face grinding machine is an integral structure. There is only one dressing arm. The two pieces of the grinding wheel will be trimmed in the same time. The stability is good. The dressing precision is high. And it is automatically dressed and compensated.

9. The position precision of the feeding and discharging plate is high: the feeding and discharging guide seat of the double side face grinding machine adopts dovetail bracket type sliding. The feeding and discharging plates can be adjusted in the horizontal and vertical directions. The adjustment is simple and quick.

Working accuracy of machine tool: (different workpieces have different accuracy):

Parallel difference | 0.01 |

Flatness | 0.01 |

Thickness difference | 0.015mm |

Surface roughness | Ra 0.8μm |

Main technical parameters (specific parameters shall be designed as required):

Project | Unit | Parameter |

Grinding wheel diameter (outer diameter × thickness × inner diameter) | mm | 750×60×50 |

Spindle speed | r/min | 770 |

Feeding speed (stepless) | m/min | 3-14 |

trimmer movement speed | m/min | 0.5-1.5 |

Moving stroke of grinding head | mm | 130 |

Grinding head motor | kw | 22×2 |

Overall dimension (L × W × H) | mm | 3500×3400×1800 |