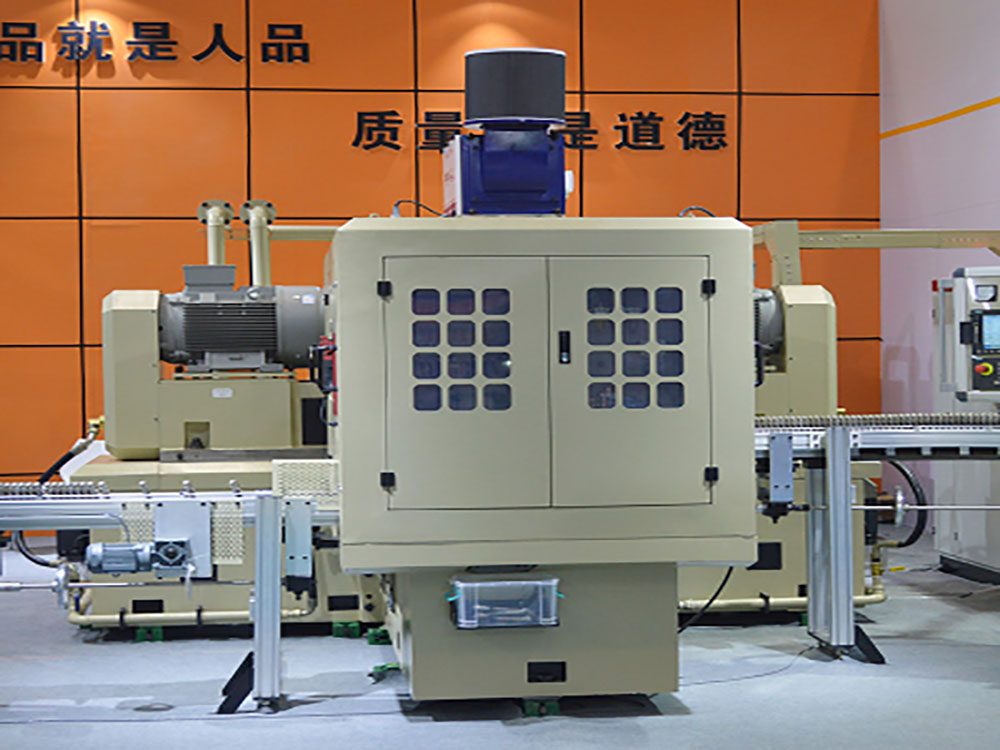

CNC Automatic Double Disc Grinding Machine SX150D-13YL

The CNC double disc grinding machine, belonging to an intelligent double disc grinding machine, can grind connecting rod with unequal thickness between two ends. It provides a reliable solution of processing technology for grinding the connecting rod with unequal thickness of the large end and the small end. It is combined with a special connecting rod conveyor belt for the connecting rod transporting. It is automatic for workpiece loading and unloading. Marposs measurement system automatically realizes 100% full inspection. Waste products are automatically isolated, and the finished products automatically enter the next process, which can be used for construction of automatic production lines. Because of its outstanding stability and high rigidity, this CNC automatic double disc grinding machine can also be used for grinding large size connecting rod such as diesel engine and other larger specifications. It is also suitable for processing other parts of different shapes and different materials after replacing the fixture.

Features and benefits:

1. This CNC full-automatic double disc grinding machine realizes the process of automatic loading and unloading, to start automatic grinding when workpieces are available and stop grinding when workpieces are not available. The measurement system achieves overall inspection and automatic compensation with the function of isolation of waste products; Waste products automatically go to the next process. It is an intelligent process that it can realize automatic dressing of grinding wheel and self-diagnosis of faults without manual intervention.

2. A waste collection box is set at the discharge position of the double disc grinding machine. When the size of the connecting rod ground is out of tolerance, the machine will automatically collect, isolate and record the waste. If two wastes occur continuously, the machine will automatically stop feeding and give an alarm, and at the same time give an audible and visual prompt.

3. The grinding area of the double-sided grinding machine is completely enclosed. The operating protective door is installed with an electric control door lock, and the machine will stop working when the door is opened forcibly. The discharging position shall be flushed with large amount of purified water. After the connecting rod is discharged, the surface of the workpiece shall be clean and free of iron filings.

4. The CNC full-automatic double disc grinding machine has the function of historical data and record query. The processing size data of all connecting rods in the past month can be queried, and statistics and linear analysis can be made. You can also check the recent grinding status of the machine and operation records.

5. The grinding machine has undergone heat insulation treatment, so that the influence of grinding heat on the grinding machine is eliminated, thus the stability and reliability of the equipment are enhanced.

6. The dresser of the CNC double disc grinding machine is of an integral structure with only one dressing arm. The two grinding wheels are dressed at the same time, so that the stability is good, and the dressing precision is high.

7. The grinding machine is equipped with an independent coolant circulation system, which has the function of constant temperature control of the coolant. The coolant system is equipped with three-stage filtration: the first stage is a magnetic drum separator, the second stage is a drum filter, and the third stage is a bag filter with a filtration accuracy of less than 15 μm and water level alarm is provided.

8. The CNC full-automatic double disc grinding machine is equipped with a water mist collection, purification and separation system, which collects and processes the water mist generated by the grinding of the machine tool, keeps the fixture and the loading and unloading area relatively dry, and makes the humidity of the air discharged outside the machine tool reach relevant standard.

Working accuracy of machine tool: (different workpieces have different accuracy):

Parallel difference | 0.01 |

Flatness | 0.01 |

Thickness difference | 0.02 |

Surface roughness | Ra 0.8 |

Model: SX 150D-13YL Main technical parameters:

Project | Unit | Parameter |

Spindle diameter | mm | Ф150 |

Grinding wheel diameter | mm | Ф800 |

Minimum feed | mm | 0.001 |

Feed Motor | kw | 1.8×2 |

Trimming motor | kw | 0.9 |

Total power | kw | 96 |

Overall dimension (L × W × H) | mm | 7000×5000×2400 |