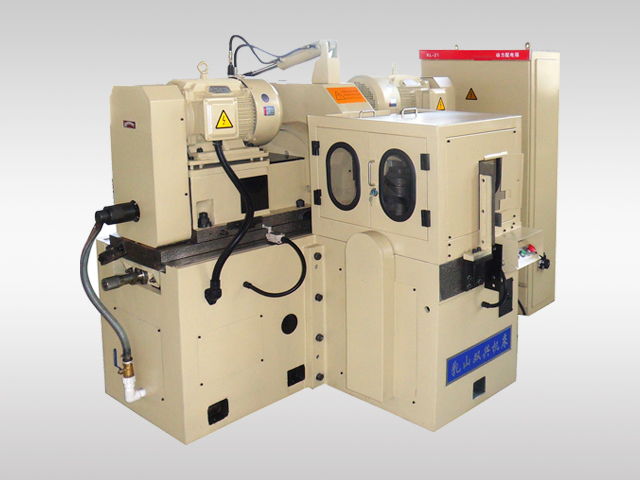

Horizontal Shaft Double Disc Grinding Machine M7650B

The horizontal spindle double disc grinding machine is widely used because of its strong versatility, simple fixture, easy and fast to switch varieties, high grinding efficiency, strong rigidity, good stability, small power, low grinding cost and low price. It can grind bearing rings, valve seats, flat pads, washers, blades, ceramic structural parts, protective clothing accessories, etc. as well as round, square, rectangular and other different shapes of the two sides of the workpieces. This horizontal shaft through-type double disc grinding machine also provides a variety of options for customers according to different needs, such as the options of automatic lifting and lowering of the grinding wheel’s cover, automatic lubrication, servo control, water circulation refrigeration filtering system and the like.

Features and benefits:

1. The bed of the horizontal shaft double disc grinding machine is designed with heat insulation to ensure that the double disc grinding machine can work continuously for a long time with good and stable precision performance.

2. The fast forward and fast backward of the grinding head of the horizontal shaft through-type double disc grinding machine are continuously maintained by hydraulic pressure, the clearance of the ball screw is successfully eliminated, and the working performance is stable and it is safe and reliable.

3. The main shaft of the double disc grinding machine is made of 40Cr material, which is treated by forging, annealing, normalizing, quenching and tempering, high-frequency quenching and stability treatment.

4. The grinding head of the horizontal shaft double disc grinding machine adopts V-shaped steel inlaid needle roller bearing guide rail and integral movement to realize grinding. Instead of spindle telescopic movement grinding, it maximizes its rigidity, large cutting depth and high precision.

5. The main shaft of the double disc grinding machine is only in charge of rotation, has no spline doing telescopic movement, so the mechanical internal friction is very small, so that the service life of the grinding machine is prolonged, and the purposes of saving energy and reducing consumption are achieved.

6. The dresser of the horizontal shaft through-type double disc grinding machine is an integral structure and belongs to an independent dressing system. It has one total dressing arm, with two grinding wheels dressing at the same time, so that the stability is good and the dressing precision is high.

7. The horizontal shaft through-type double disc grinding machine adopts the two-way double-roller rubber belt feeding mode, with large friction coefficient, strong grinding characteristics and it is not prone to slipping. It is the most ideal grinding machine for grinding various specifications of products as a single machine.

Working accuracy of machine tool (different workpieces have different accuracy):

Parallel difference | 0.002mm |

Flatness | 0.003mm |

Thickness difference | 0.01mm |

Surface roughness | Ra 0.32um |

M7650B Technical parameters:

Project | Unit | Parameter |

Workpiece diameter | mm | ¢20—¢180 |

Workpiece thickness | mm | 1.5-40 |

Grinding wheel diameter (outer diameter × thickness × inner diameter) | mm | 500×60×20 |

Spindle speed | r/min | 1060 |

Feeding speed | m/min | 2.5-12 |

Corrector movement speed | m/min | 0.5-1.5 |

Moving stroke of grinding head | mm | 120 |

Grinding head motor | Kw | (11.5)15×2 |

Overall dimension (L × W × H) | mm | 2900×2300×1600 |

Weight | kɡ | 5000 |