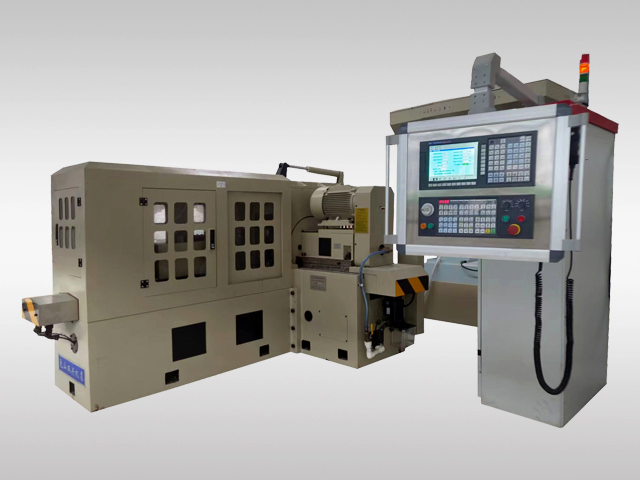

Double Disc Grinding Machine for Carbon Ceramic Brake Disc SX100D-5W

The carbon ceramic brake disc is used special materials to solve the characteristics of wear resistance and weight reduction, but it also brings the problem of difficult processing. This double disc grinding machine for carbon ceramic brake disc is designed and manufactured to adapt to the special situation of carbon ceramic brake disc. It was born to process carbon ceramic brake disc. Our company has independent intellectual property rights, and can complete the high-precision grinding of both ends of carbon ceramic brake disc. A scheme is provided for carbon ceramic brake disc production enterprises to optimize the processing technology of the carbon ceramic brake discs. A reliable guarantee is provided for the batch production of the carbon ceramic brake discs.

Features and benefits:

1. The special fixture is designed for grinding the two end faces of the carbon ceramic brake disc, which meets the process requirements of flatness, parallelism and thickness difference of the two sides of the carbon ceramic brake disc, and realizes the one-time grinding of the two sides of the carbon ceramic disc.

2. The grinding head of the carbon ceramic brake disc grinding machine moves as a whole to complete grinding, with strong rigidity and outstanding stability. Instead of spindle expansion grinding, it maximizes its rigidity, and the spindle is pre-tightened by constant force load, with large cutting depth and high precision.

3. The dresser of the carbon ceramic brake disc of the grinding machine is of an integral structure, one dressing arm and two grinding wheels are dressed at the same time, the stability is good, the dressing precision is high, and automatic dressing and automatic compensation are realized.

4. The heat insulation design of the double disc grinding machine bed of carbon ceramic brake disc ensures that the machine tool can work continuously for a long time and the accuracy is not affected.

5. The grinding wheel of brake disc grinding machine is fed by high-precision ball screw, and The guide rail adopts V-shaped steel inlaid needle roller design.

6. When the grinding wheel of the double disc grinding machine for carbon ceramic brake disc is worn to the limit size, the feeding mechanism will automatically stop feeding and give an audible and visual alarm.

7. The carbon ceramic brake disc double disc grinding machine is equipped with an independent coolant circulation system and has the function of coolant thermostatic control.

8. The coolant system is equipped with a two-stage filter: the first stage is a 6-gear filtering water tank, and the second stage is a paper belt filter with a filtration accuracy less than 20 μm and with a water level alarm function.

Working accuracy: (different workpieces have different accuracy):

Parallel difference | 0.008 |

Flatness | 0.008 |

Thickness difference | 0.015 |

Surface roughness | Ra 0.32 |

SX100D-5W Main technical parameters:

Project | Unit | Parameter |

Maximum machining diameter | mm | 480 |

Processing thickness | mm | 5-80 |

Spindle diameter | mm | Ф100 |

Grinding head stroke | mm | 120 |

Minimum feed | mm | 0.001 |

Spindle motor | kw | 18×2 |

Grinding head feed motor | kw | 1.8×2 |

Thumbwheel motor | kw | 2.5 |

Overall dimension (L × W × H) | mm | 3500×2400×1800 |